Your Most Professional Expert in One-Stop Customized Product Development

From software architecture design to hardware solution development, we leverage our most professional full-process capabilities to tailor-make high-quality, customized products for you.

- Over 20 years of OEM /ODM production experience

- Advanced manufacturing equipment

- Provision of one-stop customization and PCBA design services

- A highly experienced acoustic R&D team

- Signing the NDA for you

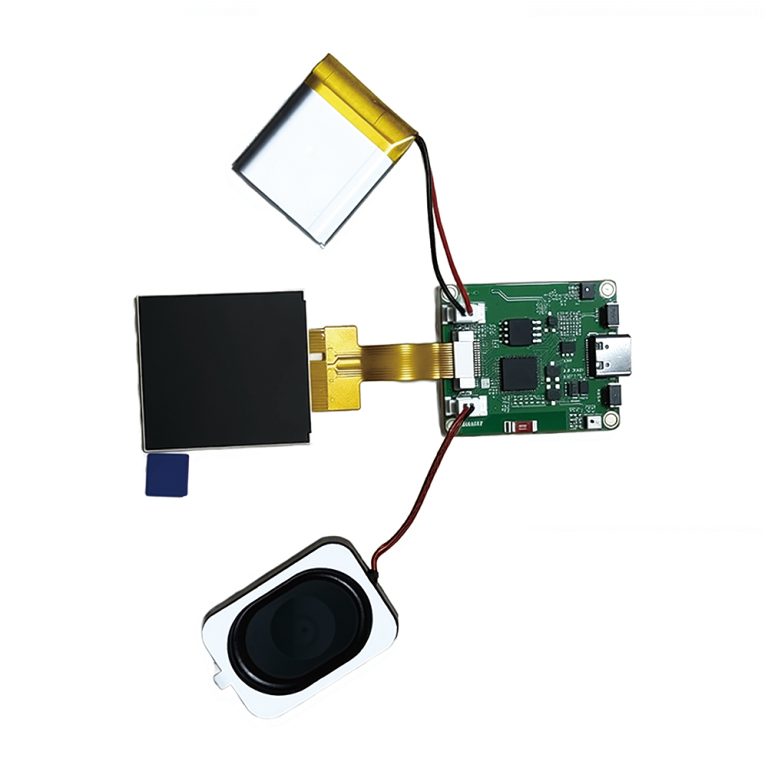

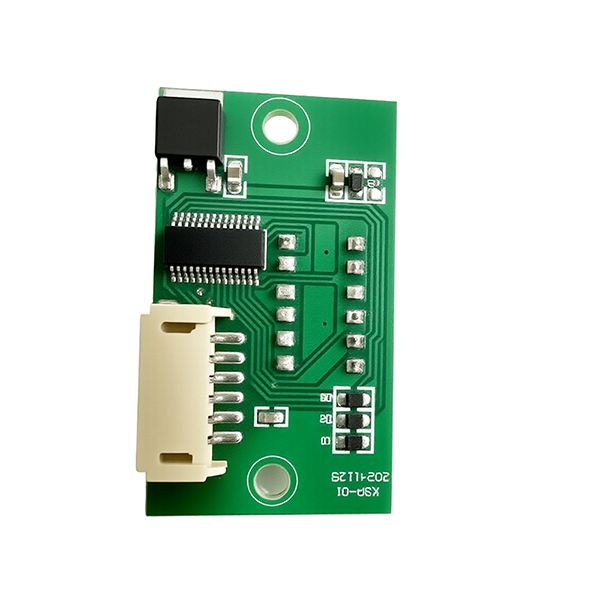

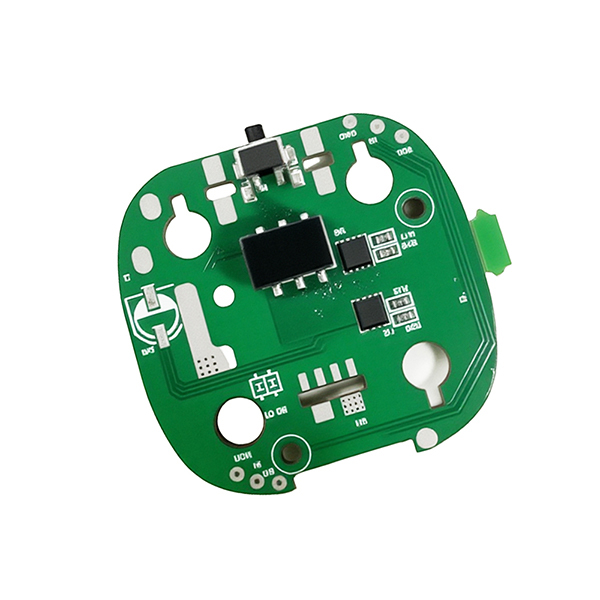

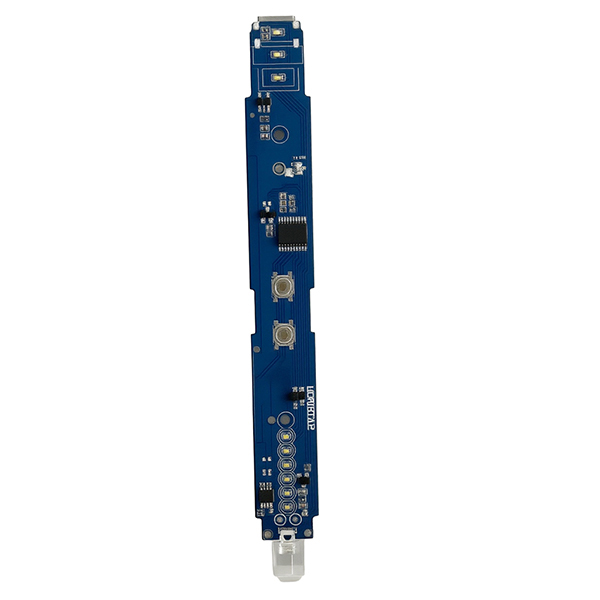

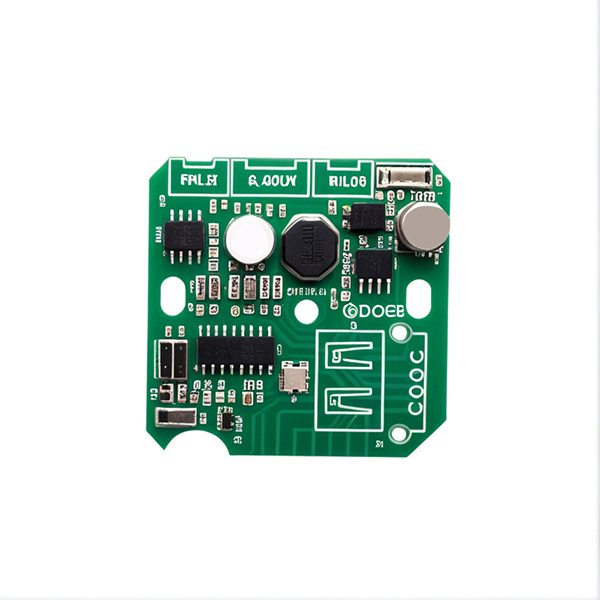

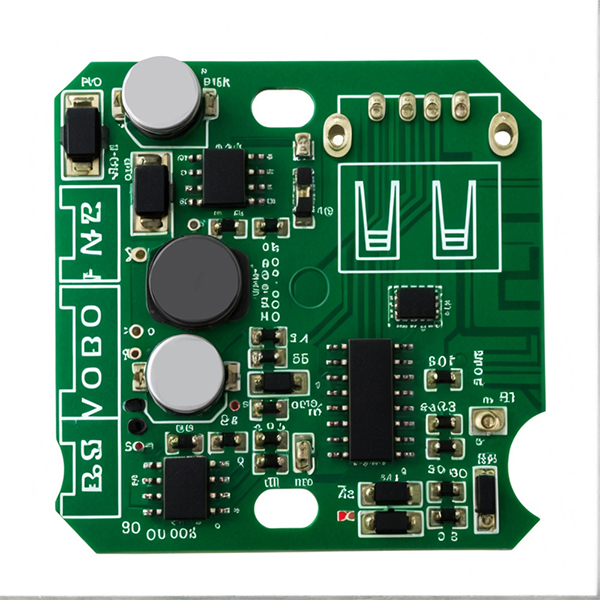

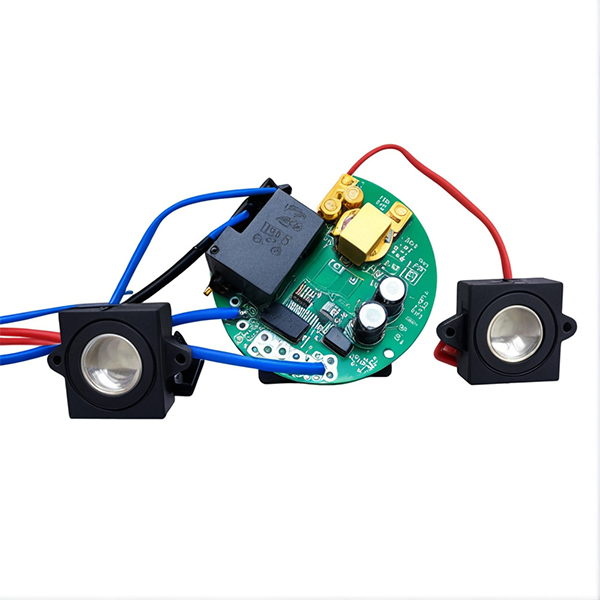

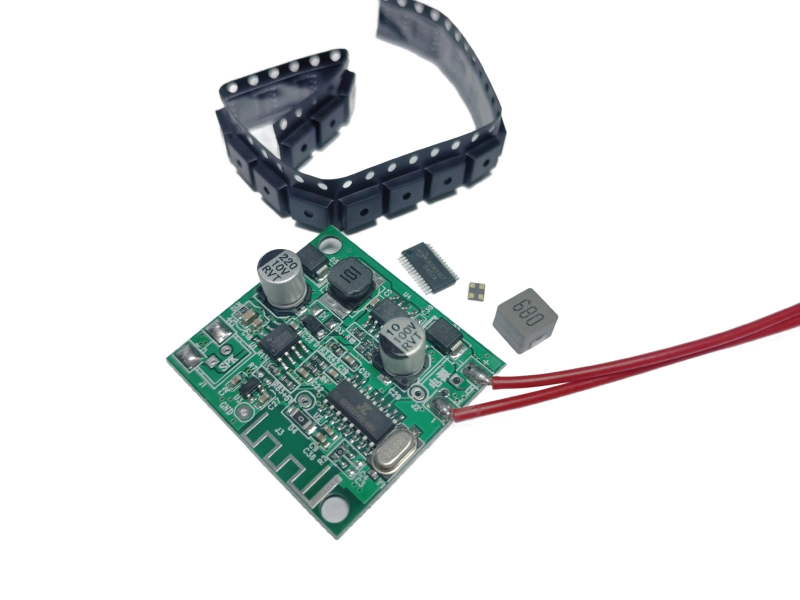

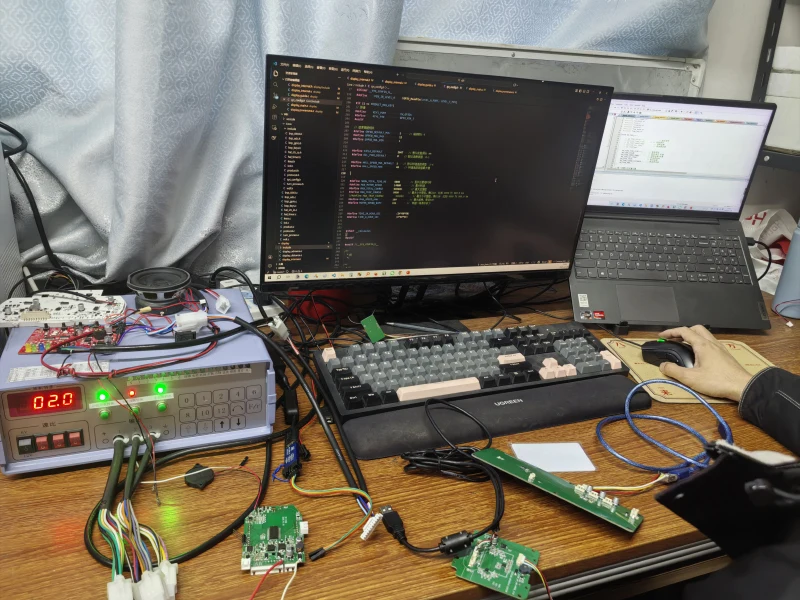

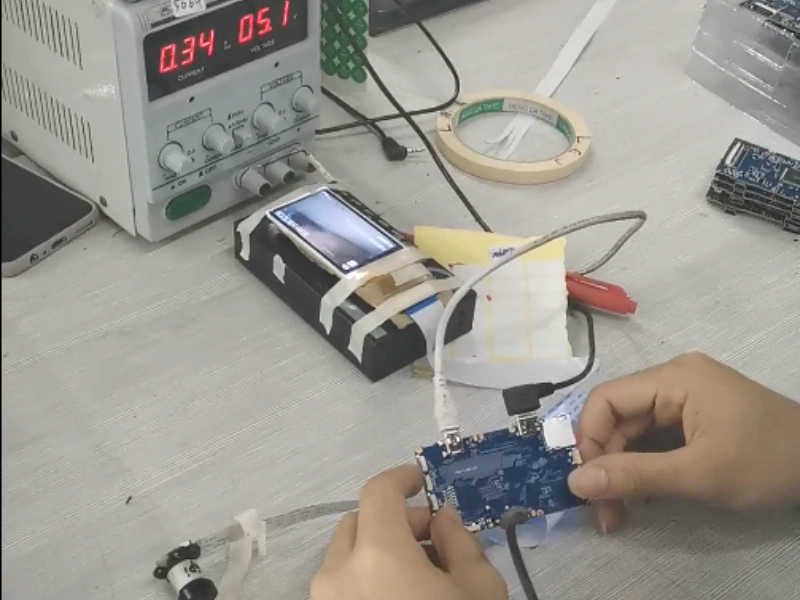

Latest Customized Products for Clients

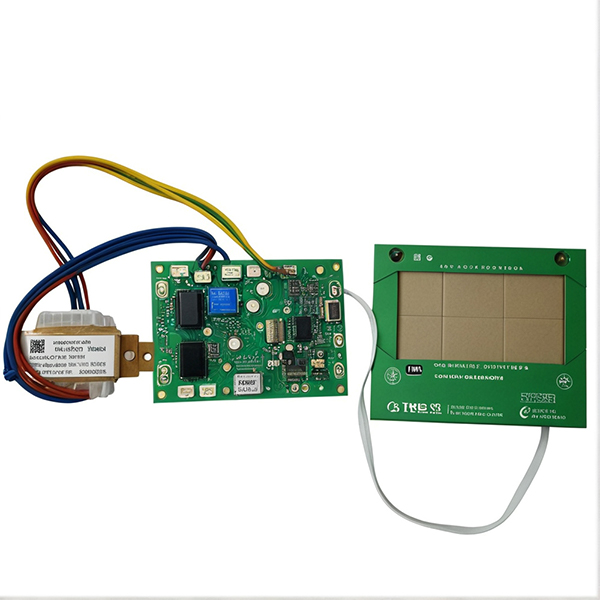

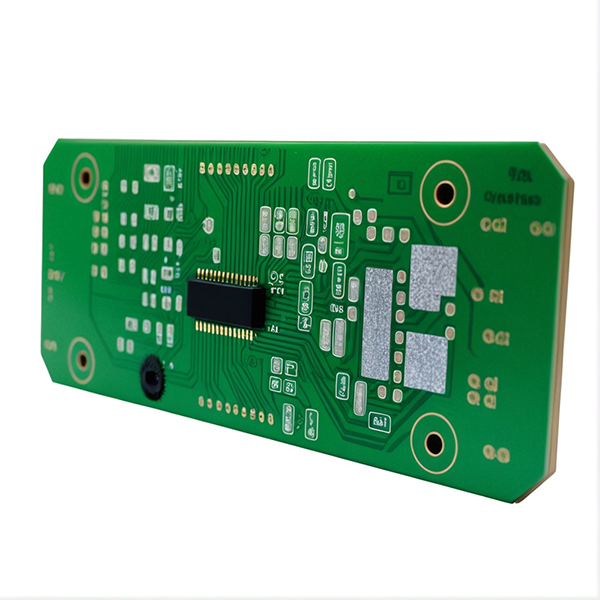

Against the backdrop of increasingly sophisticated customized product demands, ZEH leverages “integrated software and hardware structure + own manufacturing facilities” as its core competitiveness to provide you with full-link customization support. This includes PCBA design, professional debugging of audio speakers, optimization of housing structure, speaker testing services, and custom wiring harness customization — each link can deeply align with your personalized needs throughout the entire process.

Furthermore, relying on the production capabilities of its own mold factory, ZEH achieves seamless connection from the design end to the production end. It effectively addresses the three major pain points commonly faced in the industry: disconnection between design and production, slow demand response, and difficulty in controlling quality control standards. Ultimately, this helps your products quickly launch into the market and accurately align with the expected user needs and business objectives.

The core of the product’s sound quality is designed well “from the very root” — ZEH takes the PCBA audio system as the core from the source, first laying a solid foundational basis for audio performance.

- Precision PCBA audio system design to ensure lossless signal transmission;

- Optimization of the speaker sound output structure to solve issues like narrow soundstage and dispersed bass, making the sound more transparent;

- Rational design of the housing structure, which not only aligns with the optimal angle for sound quality but also reduces resonant noise.

- We can provide customization services for all types of audio electronic products. Meanwhile, to protect customers’ rights and interests, we will sign a Non-Disclosure Agreement (NDA) with you.

ZEH Audio-Your Reliable and Flexible Audio Electronic Custom manufacturer In China

ZEH Audio has been dedicated to the R&D and manufacturing of a wide range of audio electronic products for over 20 years. We welcome orders of all sizes with no minimum requirement. Backed by strong manufacturing capabilities, we serve over 300 global clients, making us your ideal, stable, and reliable manufacturing partner.

Custom your own Product Design – Bespoke Solutions for Your Needs

Ten experienced senior software design engineers and hardware design engineers are ready to meet all your product design requirements.

You only need to share your ideas and requirements with us, and we will handle the rest, ensuring your product precisely matches your design application.

Our Custom Product Guarantees

Branded Electronic Components

All raw materials are sourced from branded and certified suppliers, ensuring reliable product quality assurance.

One-Stop R&D Capability

Boasting a professional, rigorous software & hardware R&D team with years of experience and proven expertise.

Automatic Production Line

Advanced production equipment empowers enhanced production efficiency and superior product stability.

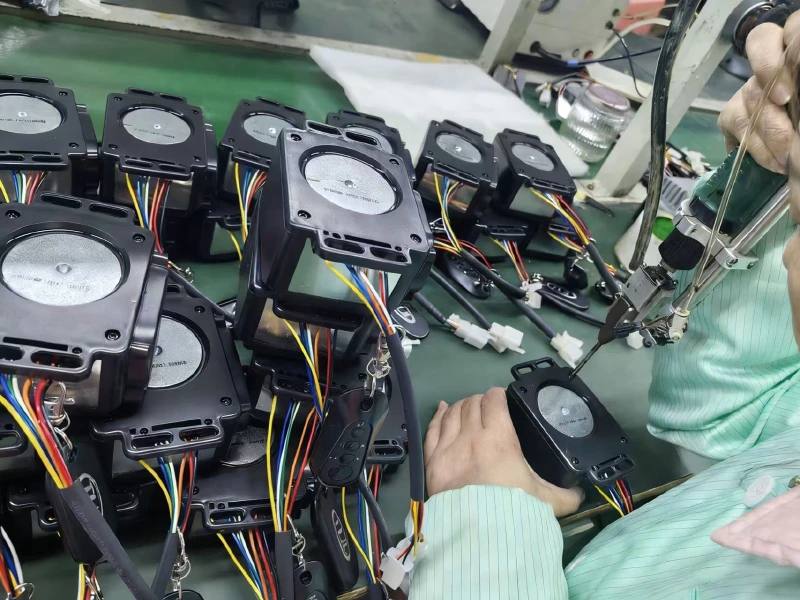

Semi-automatic Production Line

Flexible and efficient production equipment enables products to precisely meet diversified customization needs, with stable and controllable mass production quality.

Strict Quality Control

Continuous standardization and process optimization are core to quality control, guaranteeing consistent compliance and stable performance across every shipment.

Reliable Test System

Rigorous product testing guarantees long-term reliable performance, safety and durability for your products.

How do we customize a correct product

Custom Software Application

Software engineers handle application development and coding, ensuring every function precisely aligns with product requirements—delivering stable, smooth and reliable operation.

Hardware Assembly Process

Hardware engineers prioritize core hardware compatibility—ensuring impedance and power parameters of batteries, microphones, capacitors, resistors, ICs, and speakers precisely align with the power specifications of the PCBA motherboard, avoiding hardware incompatibility and suboptimal performance.

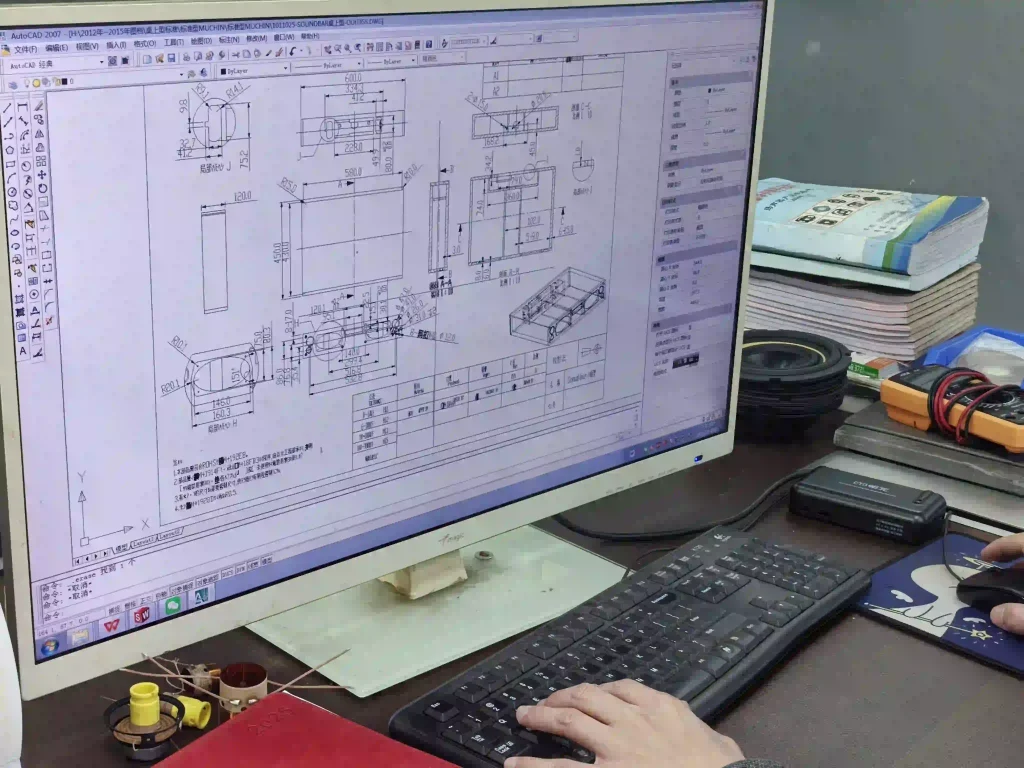

Enclosure/Housing Design

Housing dimension planning and structural design must simultaneously meet two core requirements: 1. Comply with the overall product assembly process for smooth component integration; 2. Align with the speaker’s acoustic characteristics to maximize sound output while ensuring stable acoustic performance.

Safety Performance Testing

Stringent end-to-end safety testing is mandatory to eliminate all potential hazards, ensuring full compliance with global safety standards and certifications—guaranteeing zero safety risks in product application.

Why choose ZHE Company to customize your product?

As a renowned audio expert, ZEH has built three core pillars: professional certification systems, safety control systems, and comprehensive after-sales support systems. Its professional capabilities have been widely recognized by global customers.

ZEH takes product professionalism as its foundation, deeply aligns with customers’ aspirational design needs, and covers all critical stages—from safe material selection to precise cost control. Supported by “hardware-software integration + its own mold factory”, ZEH also coordinates the adaptation of all components (including PCBA, speakers, enclosures, and wiring harnesses) to avoid a “mismatch between design and real-world application”, delivering efficient and reliable customized solutions to you.

The Customized Products Applications

The scenario essence of customized products lies in “addressing personalized needs that cannot be met by standardized products”. They need to align with both customer concepts (such as brand positioning and usage preferences) and functional requirements to create products that meet market demands. Customized products have a wide range of applications, covering various industry fields including consumer electronics, industrial manufacturing, instrument manufacturing, smart home living, medical and health care, children’s equipment, beauty and skincare devices, clothing and apparel, and cultural and creative gifts.

ZEH leverages the advantages of its integrated one-stop solution, which includes (casing + speaker + wires and harnesses + PCBA audio optimization), to customize unique products according to your requirements:

Adapted to the limited space in vehicles, able to withstand high and low temperatures/vibration environments. They also align with the brand visual identity of automobile manufacturers (e.g., casing texture) and meet in-vehicle audio interaction needs (e.g., clear voice announcements), all customized according to customer requirements.

Balancing portability and aesthetic design (to match the aesthetics of young users) with high-definition sound quality. Smart wearables need to meet the requirements of "miniaturization + low power consumption", all customized according to customer requirements.

Made of safe and non-toxic materials with soft sound quality (to protect children's hearing), adapted to children's operating habits (e.g., shockproof casings). They can also integrate brand IP to create interesting interactions, all customized according to customer requirements.

Need to highlight "creativity + memorability", align with festival/brand IP themes, and meet the needs of "scenario-based interaction" (e.g., synchronized audio playback with books), all customized according to customer requirements.

Strengths of our company

Core Logic Behind ZEH’s Customized Product Solutions,Our integrated approach addresses the “standardization adaptation dilemma” through solutions characterized by the following key attributes:

We engineer lightweight, high-temperature-resistant, waterproof, and dustproof enclosures tailored to the brand identity or specific requirements of clients. Concurrently, voice clarity across all products is optimized via PCBA audio tuning. Wire harnesses utilize anti-vibration materials to prevent signal or audio disruptions during vehicle movement and etc.

Customized enclosures incorporate diverse materials—such as matte/metallic finishes and bespoke color schemes—to align with the unique attributes of different brands. The integration of speakers with PCBA audio optimization, coupled with low-power PCBA design, extends battery life. This enables clients to develop "differentiated blockbuster products," strengthening market penetration in a homogeneous landscape through "customized aesthetics paired with premium sound quality.

All materials undergo rigorous screening to ensure full compliance with international safety certification standards.

Tailored to clients' thematic designs (e.g., traditional Chinese motifs, embossed corporate logos), LED devices feature "audio-synchronized lighting" via PCBA linkage control. Interactive innovations include book players with PCBA audio optimization for "page-turn activated audio" (e.g., picture book narration synchronization). Miniaturized, concealed wire harnesses preserve the gift's aesthetics, delivering "emotionally resonant custom gifts."

When customizing products, customers usually face several major issues, which are detailed below along with ZEH's corresponding work processes:

1. Speaker Components :

Common customer issues: The selected speakers suffer from sound distortion, insufficient volume, or burnout due to power overload, and are not suitable for the application scenario.

Installation compatibility issues: Misaligned dimensions/hole positions in the customer’s self-designed structure lead to failure to assemble, looseness, or air leakage (which causes distortion). Under high/low temperatures, moisture, or vibration, problems such as diaphragm cracking, lead oxidation, and magnetic circuit demagnetization may occur.

ZEH’s work process:

1.Acoustic engineers communicate with the customer to confirm key parameters (power, impedance, frequency response, signal-to-noise ratio, etc.).

2.Conduct COMSOL simulation and material adjustment based on sample testing.

3.Perform 96-hour power adaptation and lifespan testing before mass production.

2. Plastic Enclosure Components

Common customer issues: Most customer-designed enclosures have excessive dimensional deviations (critical dimension deviation ≥ 0.2mm) and surface defects. Excessive deviations make them incompatible with PCBA/accessories; surface defects (such as sink marks, bubbles, and flash) affect appearance and assembly.

ZEH’s work process:

1.Use high-precision plastic molds (cavity tolerance ± 0.02mm).

2.Conduct full inspection of the first article with a coordinate measuring machine (CMM), and sample inspection every 2 hours during mass production.

3.Adjust injection molding parameters to control deviations; select materials (ABS+PC, PPT, or other materials based on the customer’s product durability requirements) and dry them to remove moisture.

4.Optimize the injection molding process; adopt “manual + machine vision (0.01mm resolution)” inspection, and repair defective parts via ultrasonic technology.

3. Metal Components

Common customer issues: Insufficient machining precision/flatness and poor corrosion resistance. Specific problems include tolerance ≥ 0.05mm, flatness deviation ≥ 0.03mm/m, uneven assembly gaps, and rusting within 1–3 months in humid/salt spray environments.

ZEH’s work process:

1.Select materials based on application scenarios or customer requirements (e.g., 6061 aluminum for automotive use, 304 steel for industrial use) and etc..

2.Perform 5-axis machining (precision ± 0.01mm), followed by surface grinding (Ra ≤ 0.8μm) and laser leveling.

3.Choose surface treatments based on scenarios (e.g., cathodic electrophoresis for automotive parts, hard anodization for outdoor use) or customer requirements.

4.Conduct a 48-hour neutral salt spray test; rework any non-conforming parts.

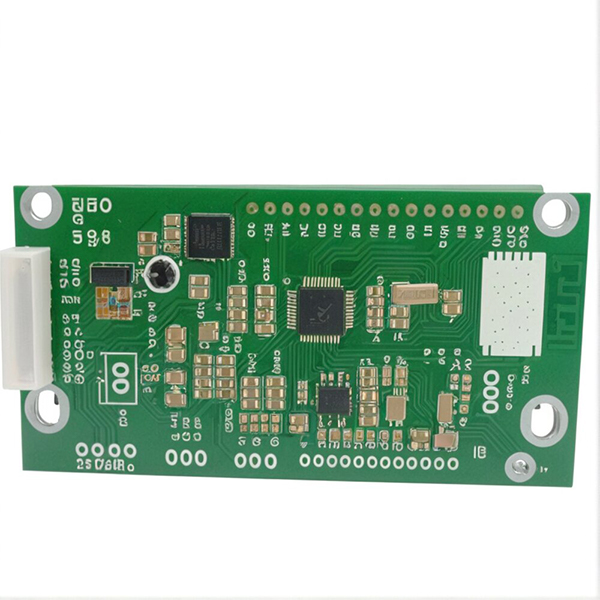

4. PCBA Components

Common customer issues: Poor soldering (cold solder joints, dry joints, bridging), mismatched component selection, and failure to meet EMC standards. These issues lead to abnormal functionality, electromagnetic interference with surrounding devices, or functional disorders caused by external interference.

ZEH’s work process:

1.Perform SMT placement (± 0.02mm) and lead-free reflow soldering with temperature control.

2.Conduct dual inspection using AOI (Automated Optical Inspection) and X-ray; accurately desolder and retest defective parts to ensure a yield rate ≥ 99.9%.

3.Select industrial/automotive-grade components based on operating conditions, establish a BOM (Bill of Materials) for customer confirmation, and conduct a 1000-hour aging test on key components at 85℃.

4.Perform a 72-hour full-load test at 85℃ before mass production.

5.Conduct Altium simulation for PCB design (e.g., circuit separation, isolation of high-frequency components); add protective measures (filter capacitors, common-mode inductors).

6.Randomly test EMC compliance (in line with GB/T 17626); adjust the design if standards are not met.

5. Wire and Harness Components

Common customer issues: Signal interference/attenuation, insufficient mechanical strength, mismatched interfaces/poor contact, wire breakage or connector detachment due to frequent bending/pulling.

ZEH’s work process:

1.Select shielded wires based on signal requirements or customer’s wire specifications (e.g., single shielding for analog signals, double shielding for digital signals).

2.Route wires away from high-voltage circuits (minimum distance ≥ 10cm); test transmission rate (e.g., USB3.0 up to 5Gbps) and bit error rate (≤ 10⁻⁹).

3.Choose TPE bend-resistant wires (withstanding 10,000 cycles of 90° bending) and multi-strand copper wires; encapsulate connectors via injection molding (withstanding 50N tensile force for 1 minute).

4.Add corrugated tubes or clips to fix vulnerable parts.

5.Select compliant connectors based on the customer’s interface requirements; conduct 1000 insertion/extraction cycles on samples and test resistance (≤ 50mΩ); mark specifications on connectors as required by the customer.