Professional Machining & Casting Manufacturer& Supplier

We specialize in delivering high-precision CNC sheet metal components (tolerances ±0.05mm) with unmatched efficiency and quality. Leveraging state-of-the-art laser cutting, CNC bending, and precision welding technologies, we transform raw materials—including stainless steel, aluminum, and galvanized steel—into custom solutions for industries like aerospace, automotive, and medical devices.

- Dimensional Accuracy: Consistent ±0.05mm tolerance ensures seamless assembly.

- Material Flexibility: Work with 20+ metals and alloys, including exotic materials like titanium.

- One-Stop Service: Design optimization, prototyping, and full-scale production under one roof.

- Certifications: ISO , CE,FCC and RoHS compliance for global markets.

Machining & Casting Series

As a core product series covering the full “casting-machining-surface treatment” workflow, ZEH AUDIO is the preferred manufacturing partner for new energy, construction machinery, and medical clients—backed by strong technical capabilities and flexible services. Its key advantages are:

- Precision + Efficiency to Fix Production Pain Points:Equipped with 5-axis CNC machining setups, the series delivers stable core dimensional accuracy of ±0.003mm. It precisely processes hard-to-machine materials (including stainless steel, high-temperature alloys) and batches of complex structural parts. Casting covers sand casting and precision investment casting (supports ≥2mm thin-walled parts), with casting density over 99.5%. Material utilization is 20% higher than traditional processes, cutting machining allowances and waste from the start.

- End-to-End Collaboration for Direct Cost & Efficiency Gains:Breaking the “casting-machining” split cooperation barrier, we deliver one-stop service from blank forming to precision finished products—no inter-facility transshipment required. Process handover tolerance is controlled within 0.01mm, shortening production cycles by 25% on average. Supplier coordination costs are also reduced by 30%. For one construction machinery client, we cut costs by over 50000 USD in six months just through less material waste.

- Custom Solutions for Multi-Industry Needs:We create custom high-performance products based on clients’ drawings and performance specs: e.g., semi-solid magnesium alloy electric drive housings for new energy automakers, and ±0.01mm precision parts for medical device firms. Full-process quality checks include X-ray inspection and CMM testing, balancing customization and stability.

From lightweight design to precision manufacturing, cost optimization to quality assurance, ZEH AUDIO’s Machining & Casting Series stays customer-focused—turning process strengths into clients’ market competitiveness. For industry-specific manufacturing needs, contact us for a custom solution.

Why choose ZEH's metal stamping for your industrial equipment?

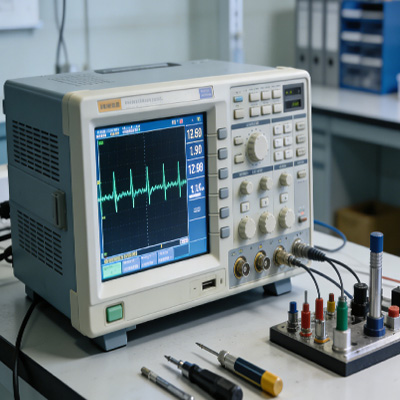

ZEH metal stamping leverages CNC precision temperature control and mold calibration technologies, ensuring dimensional tolerance of industrial equipment components is ≤0.02mm—meeting the precision assembly needs of equipment.

- Handpicked base materials like high-strength steel and wear-resistant stainless steel make stamped parts impact-resistant and industrial corrosion-resistant, extending the service life of entire equipment.

- High-speed stamping lines enable mass production, delivering cost advantages for your products. They also support custom structural designs to suit specialized high-end equipment such as various instruments, industrial devices, and electronic equipment—supporting stable operation of your products and enhancing their market competitiveness.

The Machining & Casting Applications

CNC aluminum profiles, featuring lightweight and high rigidity, serve as the core material for automation equipment frames. Typical applications include frames of automated production lines, robotic arm bases, and conveyor guide rail brackets. Through CNC high-precision cutting and drilling, they can accurately match the assembly holes of equipment, reducing subsequent debugging costs. Meanwhile, the corrosion resistance of aluminum profiles enables them to adapt to oily and dusty workshop environments, resisting deformation during long-term use and extending the service life of equipment.

Focusing on the demands for thermal conductivity and structural protection, CNC aluminum profiles are widely used in outer casings and internal supports of electronic devices. Representative products cover server chassis casings, heat dissipation chambers of new energy inverters, and borders of industrial control screens. CNC processing allows for the creation of complex heat dissipation grooves and buckle structures, which not only ensure the heat dissipation efficiency of electronic components but also protect internal circuits through one-piece molded casings, preventing interference from moisture and dust and adapting to various indoor and outdoor usage environments.

Driven by the demand for lightweight and energy-saving, CNC aluminum profiles have become a key material for new energy transportation equipment. Examples include battery pack casings of new energy vehicles—CNC milling is used to create sealing grooves and mounting holes, ensuring water and dust resistance for batteries—frames of electric motorcycles, and interior skeletons of rail transit carriages. The special-shaped cross-sections formed by CNC processing can accommodate the installation of seats and armrests, while reducing the overall weight of the carriage and lowering track load.

Aligning with the needs of consumer products for thin and light design and appearance texture, CNC aluminum profiles are applied to structural components of high-end consumer electronics and smart home devices. For instance, heat dissipation module brackets of laptops—CNC precision processing achieves ultra-thin wall structures with a thickness controllable at 1-2mm, adapting to the thin and light design of the device—casings of smart door locks, where CNC wire drawing and anodizing processes create a fine metallic texture while providing scratch-resistant and corrosion-resistant properties, and body frames of home projectors. Their lightweight design facilitates easy movement, and high-precision processing ensures the coaxiality of the lens and the body, improving projection image quality.

The Machining & Casting Advantages

For medium-to-large batch orders, this series delivers “low-cost blank forming paired with high-efficiency finishing”. Casting facilitates the rapid production of high-volume blanks, minimizing material waste. Meanwhile, standardized machining workflows shorten the per-unit processing cycle, further enhancing production efficiency.

Casting enables one-piece product formation, eliminating weak points like welds and splice joints—these are prone to fatigue cracking under long-term loads. Additionally, subsequent precision machining optimizes surface roughness (Ra ≤ 0.8μm), ensuring a tight fit between mating parts and thereby reducing the risk of wear and leakage.

It supports a diverse range of metal materials and enables customization of material performance based on application scenarios. For products demanding high strength, ductile iron or alloy steel is used for casting, combined with heat treatment and precision grinding processes—boosting hardness to HRC 50-60. For applications requiring lightweight and corrosion-resistant characteristics, aluminum alloy or stainless steel casting is adopted, paired with surface processing and anodizing/passivation treatments to improve rust protection. This versatility meets the material needs of industries including automotive, aerospace, marine, and industrial equipment.

Metal enclosures act as intrinsic heat sinks and provide robust electromagnetic interference (EMI)/radio frequency interference (RFI) shielding. This ensures the stable and reliable operation of electronic devices housed within.