Your Most Professional Plastic Injection Molding Manaufacturer & Factory

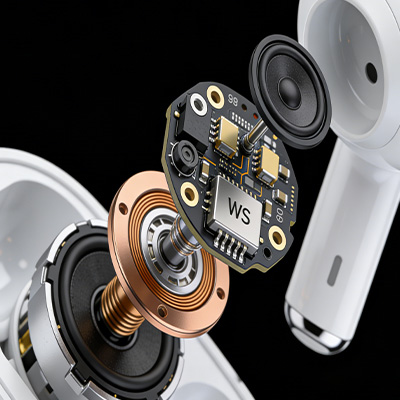

ZEH’s plastic enclosures are precision-manufactured using high-grade ABS, PC, ABS+PC,PVC and etc composite materials, delivering exceptional durability, impact resistance, and structural stability for diverse scenarios. Suitable for audio devices, PCBA motherboards, Medical,Consumer electronics,automobile,electrical equipment and instrument applications, our enclosures meet industry-grade protection standards.

- Multiple Material Options to Meet Diversified Product Needs: We offer customization of various materials including ABS, PC, ABS+PC, PP, PA, and POM, with support for tailored adjustment of material performance.

- High-Precision Mold Technology for Structural Stability: Our in-house mold R&D team delivers integrated implementation from structural design to mold opening.

- One-Stop Customization to Shorten Delivery Cycles: Covering the full process of “design – prototyping – pilot production – mass production”, we support both OEM and ODM service modes.

- Audio-Scenario-Specific Optimization for Acoustic Requirements: Leveraging our technical expertise in the audio field, we provide custom acoustic hole drilling and sound insulation structure design for product enclosures.

- Diversified Production Capabilities: We support small-batch pilot production and large-scale mass production, enabling rapid response to order volume adjustments.

- Surface Treatment Processes: Customizable diversified surface treatments are available per customer requirements, such as frosting, laser engraving, silk-screen printing, and spray coating.

Plastic enclosure Series

ZEH is a trusted manufacturer of high-performance plastic enclosures, expertly crafted from premium, application-matched materials:

- ABS plastic: Ideal for heavy-duty industrial use, Or ABS+PC

- Polycarbonate (PC): Shatterproof & UV-resistant (perfect for outdoor/medical equipment)

- PVC: Cost-effective corrosion protection (great for chemical environments)

- Nylon: High tensile strength (handles mechanical stress)

- Fiberglass-reinforced plastic: Extreme temperature resilience (for aerospace/automotive)

Each material is rigorously tested to solve your biggest pain points:

- Resists impacts up to 50J — no more damaged internal components from drops or collisions

- Withstands 15+ years of corrosion in saltwater/chemical exposure — cuts replacement costs

- Maintains structural integrity from -40°C to 120°C — zero downtime in freezing or high-heat settings

- Repels dust/moisture (IP65+ rated) — sealed protection for critical gear

Engineered specifically for demanding industries: manufacturing, marine, telecommunications, medical, and more.

ZEH’s plastic enclosures keep your mission-critical electronics and industrial equipment running uninterrupted — reducing maintenance headaches and extending your asset lifespan.

Why Choose ZEH Plastic molding For Your Device Design?

Trusted by 500+ global brands, ZEH offers one-stop custom plastic molding solutions—from mold R&D, prototyping to mass production—with ±0.05mm precision, acoustic cavity optimization for speaker enclosures, and seamless PCBA/wire harness integration. All casings pass RoHS/REACH certification and 1000+ aging tests, meeting EU/NA market standards. We cut lead times and supply chain costs, plus provide laser engraving/silk-screen finishes.

The Plastic Injection Molding Applications

With diversified material selection, precise structural design, and acoustic performance optimization capabilities, ZEH custom plastic shells are widely applicable to different core fields, providing “protection + function” dual-excellence solutions for products in different scenarios:

1.Suitable for speaker enclosures, Bluetooth speaker cavities, earphone charging cases, and audio receiver protective shells. Exclusive acoustic cavities and sound-transmitting hole layouts can be customized to effectively avoid resonance and sound distortion, balancing shell protection and audio device acoustic performance.

2.Covers portable smart speaker enclosures, smart home control boxes, and vehicle-mounted audio terminal casings. Provides personalized appearance processes such as frosting, high-gloss finish, and laser engraving, while meeting the lightweight and high-low temperature resistant requirements of vehicle and household scenarios.

Applied to PCBA motherboard protective shells, smart sensor housings, and electronic control module casings. Supports reserving precise heat dissipation channels and interface holes, and can customize insulating and anti-EMI materials to ensure the stable operation of precision components.

Adapts to industrial audio monitoring equipment enclosures, PLC control module casings, and industrial control sensor protective shells. Uses flame-retardant and impact-resistant modified plastic materials, passes industrial-grade aging tests, and adapts to complex industrial operating environments.

Used for portable medical audio detector enclosures, small monitor control boxes, etc. Selects medical-grade environmentally friendly plastics, complies with RoHS/REACH and basic compliance standards of the medical industry, ensuring safe adaptation of equipment.

Strengths of our company

Backed by in-house mold R&D, injection molding lines, and technical expertise in the audio field, ZEH offers end-to-end custom plastic shell services from structural design and material selection to mass production and delivery. Our products seamlessly match the assembly requirements of core components such as speakers and PCBA motherboards, combining functional practicality with customized appearance to help customers quickly launch products and seize market opportunities.

We support full-dimensional customization spanning material selection, structural design, and surface finishing. Special plastic materials with flame-retardant, impact-resistant, and high/low temperature-resistant properties can be tailored according to the application scenarios of customers’ products. Meanwhile, we offer diverse surface treatment processes including frosting, high-gloss finishing, spray coating, laser engraving, and silk-screen printing. Additionally, we can optimize the shell and acoustic sound-transmitting structure based on the characteristics of audio products, achieving dual alignment of functionality and appearance.

A full-process quality control standard has been established. We implement inspection procedures that exceed industry standards across all stages: from component testing of incoming raw materials, to dimensional accuracy verification of injection-molded parts (with tolerances controllable within ±0.05mm), and to wear resistance, aging resistance, and environmental compliance testing of finished products. This ensures that all products meet the requirements of international market environmental certifications such as RoHS and REACH.

Based on long-term technical expertise in the audio equipment field, we can optimize the acoustic structure of plastic shells for products such as speakers and audio terminals (e.g., customized sound-transmitting hole layout and cavity sound insulation design). This addresses common issues of traditional plastic shells like sound distortion and resonance, enabling the shell to not only fulfill a protective function but also enhance the product’s acoustic performance. Meanwhile, through independent mold R&D, centralized raw material procurement, and collaborative production line operations, we realize refined cost control and provide customers with cost-effective solutions while ensuring product quality.

FAQs

Customizing motherboards for kids’ devices centers on safety prioritization and child-centric scenario adaptability, adopting a standardized, targeted customization workflow to strike a seamless balance between functionality and protective capabilities. The detailed steps are as follows:

1. Define Core Product Requirements

First, map out the device’s intended use cases (e.g., early education devices, kids’ smartwatches, educational toys), functional modules (positioning, voice interaction, sensors), and safety benchmarks. Outline kid-specific safety requirements—including low radiation, interfaces compatible with food-grade materials, and short-circuit prevention—while validating compliance with relevant children’s safety certifications (e.g., China Compulsory Certificate (CCC) for children’s products).

2. Solution Customization & Prototype Development

Based on the defined requirements, engineers incorporate low-power chips into the motherboard architecture to extend battery life, integrate anti-misoperation circuit safeguards, and minimize the motherboard footprint to align with the compact form factors of kids’ devices. Following the finalization of the initial solution, a prototype motherboard is rapidly fabricated to validate functional compatibility, safety, and stability.

3. Testing & Mass Production Launch

Comprehensive multi-dimensional testing is imperative, covering safety voltage withstand tests, drop and shock resistance evaluations, and functional compatibility assessments to ensure full adherence to children’s product safety standards. Once all tests are passed, mass production can kick off. Additionally, dedicated after-sales technical support is provided to guarantee the long-term reliable operation of the motherboards.

The entire process is anchored in the unique needs of children’s usage scenarios, not only meeting the device’s functional demands but also fortifying a robust safety barrier.