Your Professional Two-color or Multi-colors Plastic Injection Molding Manufacturing

We are an integrated engineering plastic service team specializing in smart manufacturing and acoustics. With over 20 years of deep-rooted expertise in the industry, we deliver one-stop solutions spanning R&D, design, production, and final delivery.

- 20 years of deep immersion in smart manufacturing & acoustics, offering full-process customized plastic services (including mold development, injection molding, and assembly).

- Senior engineers paired with imported precision equipment, providing comprehensive support for plastic product molding—spanning R&D, design, production, and delivery.

- One-stop service for plastic components: end-to-end support for mold development, injection molding, spray painting, and assembly. Our robust manufacturing capabilities deliver peace of mind, cost savings, and higher efficiency.

- Professional full-cycle services for plastic products: from design and molding to delivery, backed by precision guarantees and simplified supply chains for enhanced peace of mind

Two-color or multi-colors Plastic Injection Molding Series

Supported by a professional design team, ZEH delivers end-to-end service support for plastic products—covering everything from initial design to final delivery. In the pre-production phase, we offer free drawing revisions and 3D prototyping to help you quickly validate design concepts, ensuring your ideas are translated into tangible results with precision. Leveraging our industry expertise, we also optimize product design structures to mitigate production risks at the source, guaranteeing smooth and accurate manufacturing of plastic molds and components.

Upon entering mass production, we strictly select safe and compliant plastic materials that balance product performance and usability. We then provide full-process oversight of plastic housing molding and surface treatment, maintaining rigorous quality control over every detail. Finally, we complete standardized packaging and shipping, eliminating the need for you to coordinate multiple parties. This allows for a hassle-free and efficient product launch experience.

We boast a team of senior technical and structural engineers, skilled in developing and designing plastic and metal molds, as well as delivering tailored solutions. Our core offerings encompass precision molds, injection molds, and injection-molded plastic products. We provide full-process supporting services—including injection molding, spray painting, silk screening, pad printing, electroplating, and finished product assembly—to streamline our clients’ supply chains. Equipped with advanced equipment such as imported CNC machining centers, EDM machines, mirror EDM machines, and laser cutting machines, we guarantee the precision of both molds and products, enabling clients to cut costs and enhance product efficiency.

Why choose ZEH for manufacturing your plastic housing products?

We specialize in premium customization of plastic components across all sectors. During structural refinement, we integrate electromagnetic shielding or circuit board design to ward off signal interference, while perfectly accommodating the installation requirements of precision electronic parts.

Our dimensional precision is calibrated to micron-level standards, ensuring seamless alignment between plastic enclosures, circuit boards, and interfaces. This eliminates any risk of loosening, enabling your products to operate safely and launch successfully in the market.

The Two-color or Multi-colors Plastic Parts Applications

Products such as smart speaker casings, smart door lock panels, temperature and humidity sensor housings, and smart curtain control panels adopt flame-retardant PC materials (complying with the UL 94 V0 standard). Their surfaces undergo silk-screen translucent treatment (to adapt to light display). The structural design reserves interface positions for compatibility with wireless module installation, while balancing the safety, functionality, and minimalist appearance of smart home products to fit the integrated design of home scenarios.

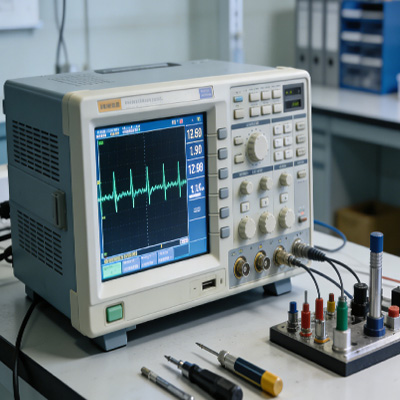

Products including multimeter casings, oscilloscope housings, sensor protective shells, and industrial controller panels use high-strength ABS/PC alloy materials (impact-resistant and oil-resistant). Their surfaces are treated with sandblasted anti-slip processing. Structural optimization enhances sealing performance to achieve dust and water resistance (IP54 rating). This meets the needs of complex industrial workshop environments (impact, oil contamination, dust) and ensures the accuracy and service life of the instruments.

Products like baby thermostatic kettle casings, bottle sterilizer frames, baby monitor housings, children’s car seat accessory shells, and casings for children’s toys and electronic devices are made of food-contact-grade PP materials (BPA-free). Their surfaces feature smooth rounded edge treatment (for anti-collision). These products have passed FDA certification, and their structural design avoids the risk of small parts falling off. They comply with strict safety standards for maternal and infant scenarios (no harmful substances, anti-injury) while balancing product functionality and safety for parent-child use.

Products such as outdoor flashlight casings, action camera protective shells, camping light housings, and portable projector casings adopt drop-resistant ABS/PC materials (withstanding 1.5-meter drops). Their surfaces are coated with anti-ultraviolet coating (to prevent fading). The structural design improves waterproof performance (IP68 rating) and meets the drop-resistant, waterproof, and sun-resistant requirements of outdoor scenarios, ensuring stable use of the equipment in outdoor environments.

The Two-color or Multi-colors Plastic Parts Advantages

Strictly adhere to the selection of plastic raw materials that meet industry safety standards, exclude substandard materials, eliminate the risk of hazardous substance release at the source, and ensure end-user usage safety.

The product has been awarded multiple authoritative certifications, such as RoHS and FDA. It is in compliance with domestic and international environmental protection and safety regulations, fulfilling compliance requirements across diverse application scenarios.

Establishment of a multi-stage quality inspection system enables full-process oversight, covering raw material inbound inspection, production and processing, and finished product testing. It also incorporates specialized testing for anti-slip performance, heat resistance, and impact resistance to uphold consistent product quality.

Seamless integration of the entire workflow, spanning from “precision structural design → standardized production → rigorous quality control → safe packaging and shipment”. This workflow encompasses simultaneous oversight of design rationality and delivery safety, so as to enhance delivery efficiency.

FAQs

1. Dimensions: To protect the customer’s technical privacy, a Non-Disclosure Agreement (NDA) can be signed. Subsequently, the internal structural dimension drawings (such as component installation position dimensions and avoidance space design) will be repeatedly optimized based on the customer’s needs until the customer confirms there are no dimensional issues or interference risks, and then 3D sample service will be provided. Only after the 3D sample is confirmed can official mold production proceed.

2. Space Optimization: Reasonably plan the installation areas for various components based on the battery weight (to avoid center of gravity shift), the speaker’s acoustic requirements (to reserve sound emission space), and the circuit board’s interface position (to facilitate external wiring). At the same time, reserve sufficient assembly clearances (e.g., 0.2-0.5mm) between components and the inner wall of the enclosure, as well as between components. Additionally, avoid key parts such as circuit board solder joints and battery electrodes to prevent crushing or damage to components during installation and avoid interference between components.

3. Surface Treatment: Customize the LOGO presentation method (such as screen printing, laser engraving, or other processes; for metal enclosures, anodizing and coloring can be added) according to the customer’s brand positioning. Meanwhile, additional surface treatments can be supplemented (e.g., spray painting and frosting for plastic enclosures, sandblasting for metal enclosures, etc., made according to customer requirements) to balance appearance texture and service durability.

4. Safety Performance: Determine the enclosure’s protection level based on the usage environment, and then select materials accordingly. Examples of impact-resistant materials include ABS, PC, PE, PP, and aluminum alloy, which offer shock resistance, high-temperature resistance, and hard object impact resistance. These materials protect both internal components and external materials from the material perspective.