07

We produce industry-specific plastic enclosures from environmentally certified raw materials, meeting diverse application needs with high-quality customized solutions:

- Safe & Controllable Raw Materials: Select safety and non-toxic certified materials (ABS, PC, ABS+PC, PP, PA, etc.) as per customer requirements.

- Customized Structural Design: Produce based on customer drawings and offer structural design optimization proposals.

- Diversified Surface Treatments: Customize processes like laser engraving, silk screening, matte finishing, and spray painting to meet different functional and aesthetic needs.

- Compliance Assurance: All products meet international safety certification standards with available corresponding certification reports.

- Efficient Delivery & Quality Control: Support rapid prototyping and implement a full-process quality control system.

- High-Standard Performance Compliance: Strictly control dimensional accuracy, meeting requirements for waterproof, high/low temperature resistance, and other tests.

- Multi-Dimensional Material Matrix:Premium raw materials (ABS, PC, ABS+PC, PP, PA) with impact strength ≥30kJ/m² and flexural modulus up to 2500MPa. High-strength, shatter-resistant performance ensures durability against drops and stability in harsh outdoor environments.

- All-Round Protection:Naturally insulating materials eliminate leakage risks; corrosion resistance withstands acid, alkali, and oil erosion. IP54-IP68 rating builds an all-weather safety barrier for internal components.

- Extreme Lightweight:1/3 the weight of metal enclosures, enhancing product portability and reducing shipping costs. Ideal for handheld devices, automotive accessories, and easy daily use.

- Versatile Customization:Multiple surface finishes (matte, glossy, spray coating, electroplating) + full Pantone color range. IMR/IML processes enable gradient textures, elevating product tech aesthetics instantly.

- Ergonomic Design:Signal-friendly structure ensures uncompromised smart product performance. Streamlined grip + smooth, fingerprint-resistant surface balances functionality and aesthetics—perfect for high-touch scenarios (handheld terminals, smart home devices).

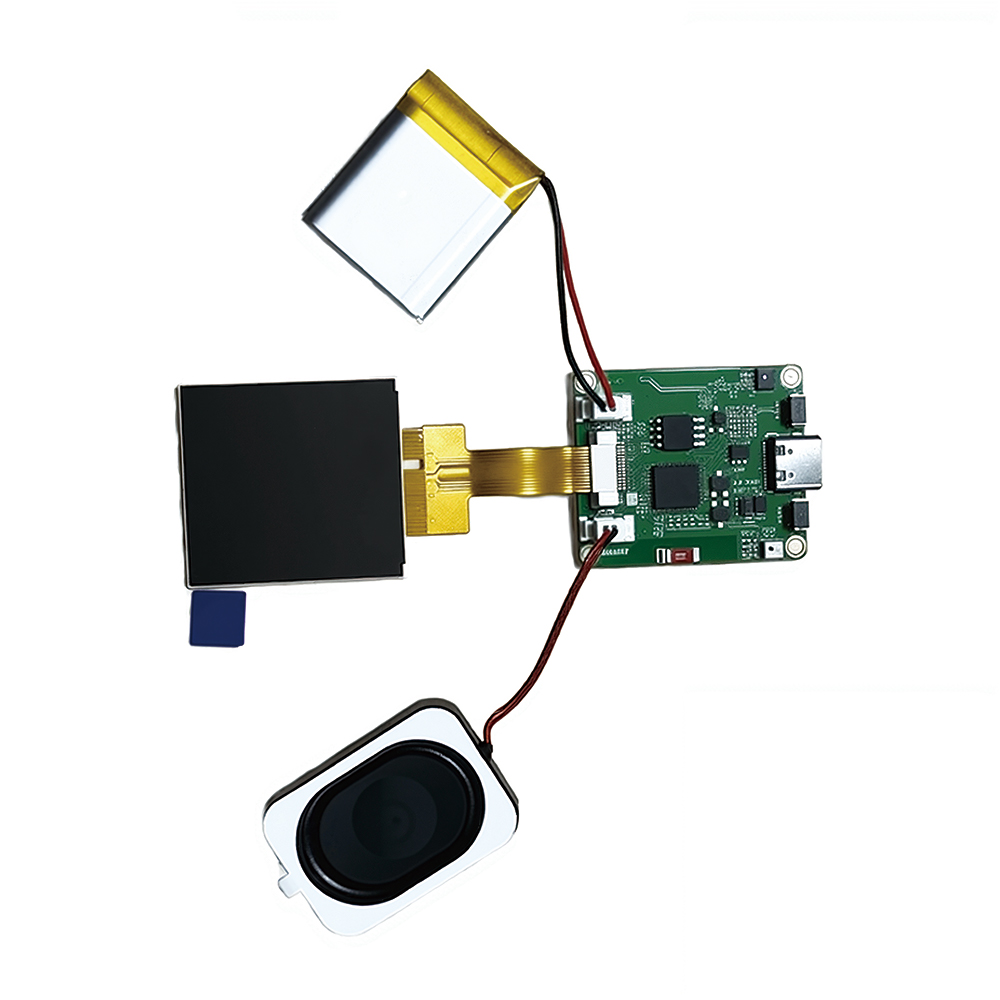

- Easy & Efficient Assembly:Precise interface cutouts and card slot designs simplify component installation, reducing labor costs and assembly errors.

The Plastic enclosure & shells & Casings Descriptions

- As a professional plastic mold injection manufacturer and supplier, we provide high-quality custom plastic enclosures. Crafted with durable materials and precision molding technology, they offer excellent resistance to high/low temperatures, drops, dust, moisture, and impacts—effectively protecting internal components of electronic devices.

- Targeting electronic manufacturers, equipment vendors, and consumer electronics brands, we support personalized customization of size, shape, color, interface, and process. With rapid prototyping and mass production capabilities, our enclosures are widely used in industrial control, consumer electronics, medical devices, IoT, and other fields.

- Backed by ISO-certified production lines and fast lead times, our one-stop plastic enclosure solutions help you reduce procurement costs and accelerate time-to-market. Export-grade quality balances functionality and aesthetics, meeting diverse application requirements.

Get Free Quote of Your Plastic Shells

We possess high-precision mold development capabilities, enabling us to customize precisely according to equipment dimensions and functional requirements. This guarantees perfect fit between the enclosure and the device body, enhancing product texture. Through strict raw material selection and factory inspection, our enclosures are impact-resistant and anti-aging, helping customers reduce after-sales maintenance costs. Meanwhile, we optimize production processes to shorten customization cycles, supporting customers in accelerating product launch. From demand communication to after-sales follow-up, ZEH provides full-process services, making customization more hassle-free.

The Plastic enclosure & shells & Casings Applications

For products such as smartphone/tablet cases, wireless earbud housings, smartwatch cases, and power bank housings, we use high-strength PC/ABS raw materials for impact and scratch resistance. These materials are paired with processes like nano-coating (anti-fingerprint) and 3D hot stamping (customized appearance). All products comply with the RoHS 2.0 environmental certification, meeting the lightweight and high-aesthetic requirements of consumer electronics. They also help create a differentiated appearance, ensure product durability, and lay the groundwork for the upgrading of consumer electronic products.

For items including control panel housings of rice cookers/microwaves, TV casings, air purifier filter frames, coffee machine bodies, and robot vacuum housings, we adopt high-temperature resistant PP/PS raw materials (withstanding 120-150℃), with spray-painted wear-resistant treatment on the surface. The products have obtained 3C certification. Structural optimization reduces assembly processes and lowers production costs for home appliance manufacturers, while balancing the high-temperature resistance functionality and appearance texture of home appliances, in line with the safety and environmental requirements of household scenarios.

For medical devices such as monitor housings, blood glucose meter housings, infusion pump frames, medical cart panels, and medical testing equipment housings, we select medical-grade PE/PP raw materials (sterilizable and corrosion-resistant), with halogen-free and environmentally friendly surface treatment. All products meet ISO 13485 certification, and their structural design includes reserved disinfection spaces. These features satisfy the strict sterility and disinfection resistance requirements of medical scenarios, ensuring the long-term stable operation of the equipment.

For parts like car central control panel housings, car charger housings, window lift button frames, and trunk storage box housings, we use weather-resistant ABS/PA raw materials (resistant to high and low temperatures of -40~80℃ and UV rays), with wear-resistant coating on the surface. The products comply with IATF 16949 certification. Structural optimization enhances shock resistance, and the components adapt to complex automotive working conditions (high/low temperatures, vibration), ensuring no aging or deformation during long-term use.