5052/7075 High-Quality Aluminum Alloy with High Corrosion Resistance

5052 High-Quality, High-Corrosion-Resistance Aluminum Alloy,Precision-manufactured from high-purity aluminum substrate, this alloy finds application in outdoor brackets, electronic device enclosures, heat dissipation components, among other applications. We provide custom machining services. Boasting excellent corrosion resistance—demonstrated by exceptional performance in salt spray testing—along with lightweight characteristics (60% lighter than steel by weight) and superior formability, it enables your products to achieve cost reduction while boosting durability.

- Prominent High Corrosion Resistance: As a core advantage, aluminum alloy materials can withstand humid conditions and outdoor exposure, delivering excellent performance in salt spray tests. They minimize post-production rusting and reduce maintenance costs effectively

- Significant Lightweight Advantage: Aluminum alloy boasts a density of approximately 40% that of steel (i.e., 60% lighter than steel), which can reduce the overall weight of equipment and lower transportation and installation costs.

- Superior Machinability and Formability: Aluminum alloy exhibits excellent performance in stamping and cutting processes, enabling it to meet the precision structural requirements of electronic enclosures, heat dissipation components and other parts, thereby enhancing production efficiency.

- Exceptional Adaptability Across Multiple Scenarios: Aluminum alloy materials can be stably applied in fields such as outdoor brackets, electronic enclosures and heat dissipation components, eliminating the necessity of switching materials for different application scenarios.

- Dual Value of Cost Reduction and Efficiency Enhancement: Aluminum alloy not only achieves comprehensive cost reduction through its lightweight property, but also prolongs product service life with its durability. Meanwhile, it helps customers enhance the competitiveness of their products.

Aluminum Alloy Description

As a professional aluminum alloy supplier and manufacturer, the high-end aluminum alloy materials we select have three core features:

- High Strength & Fatigue Resistance: Tensile strength ≥500MPa via heat treatment, with no deformation or cracking under long-term vibration/impact.

- Excellent Thermal Stability: Stable thermal expansion coefficient (≈23×10⁻⁶/℃) between -40℃~180℃, no obvious dimensional deviation from sudden temperature changes.

- High Corrosion Resistance, Lightweight & Machinability: Resists humidity/outdoor environments (prevents rust); 60% lighter than steel (cuts transport/installation costs); easy to process for precision structures.

We offer direct factory supply, exporter-grade quality control, and customized aluminum alloy processing with full-process oversight. Our company provides cost-effective products to help customers reduce maintenance investment, boost production efficiency, enhance end-product durability, and meet multi-scenario production needs.

Get Free Quote of your Aluminum Alloy enclosure

We specialize in crafting high-end aluminum alloy enclosures that flaunt high precision, corrosion resistance, lightweight build, and easy processability. Beyond that, we tailor a wide range of enclosures to your unique needs, helping boost your products’ market competitiveness significantly.

Aluminum Alloy Applications

The marine environment poses critical challenges: high salt spray and humidity cause rapid corrosion of ordinary metals, while heavy components drive up hoisting/transport costs and safety risks during offshore installation/maintenance.

High-end aluminum alloys stand out here with targeted advantages:

- Superior corrosion resistance: Shields brackets and connectors from salt spray erosion, eliminating frequent replacements;

- 60% lighter than steel: Cuts transportation and hoisting costs for marine buoy brackets, offshore platform guardrails, and similar parts;

- Excellent machinability: Fits precision structural needs of special-shaped pipe fixtures on platforms.

- Its specific applications include lightweight, salt-spray-resistant components like marine monitoring equipment enclosures, small offshore platform structures, and marine communication device brackets.

Hydrogen energy equipment (e.g., fuel cells, hydrogen storage tanks) faces three key demands: resistance to hydrogen embrittlement (a major metal failure risk in hydrogen environments), lightweight design for vehicle-mounted/portable use, and high precision for complex flow channels.

High-end aluminum alloys address these needs with standout strengths:

- Anti-hydrogen embrittlement & corrosion resistance: Withstands hydrogen embrittlement and electrolyte erosion, ensuring long service life of core components;

- Lightweight property: Meets weight-reduction requirements of vehicle-mounted hydrogen energy systems;

- High-precision machinability: Enables precise forming of micro-channels in fuel cell bipolar plates, while its high strength supports the external fixing structure of hydrogen storage tanks.

- Its specific applications cover core parts requiring “hydrogen embrittlement resistance + lightweight + precision,” such as fuel cell bipolar plates, vehicle-mounted hydrogen storage tank frames, and portable hydrogen generator enclosures.

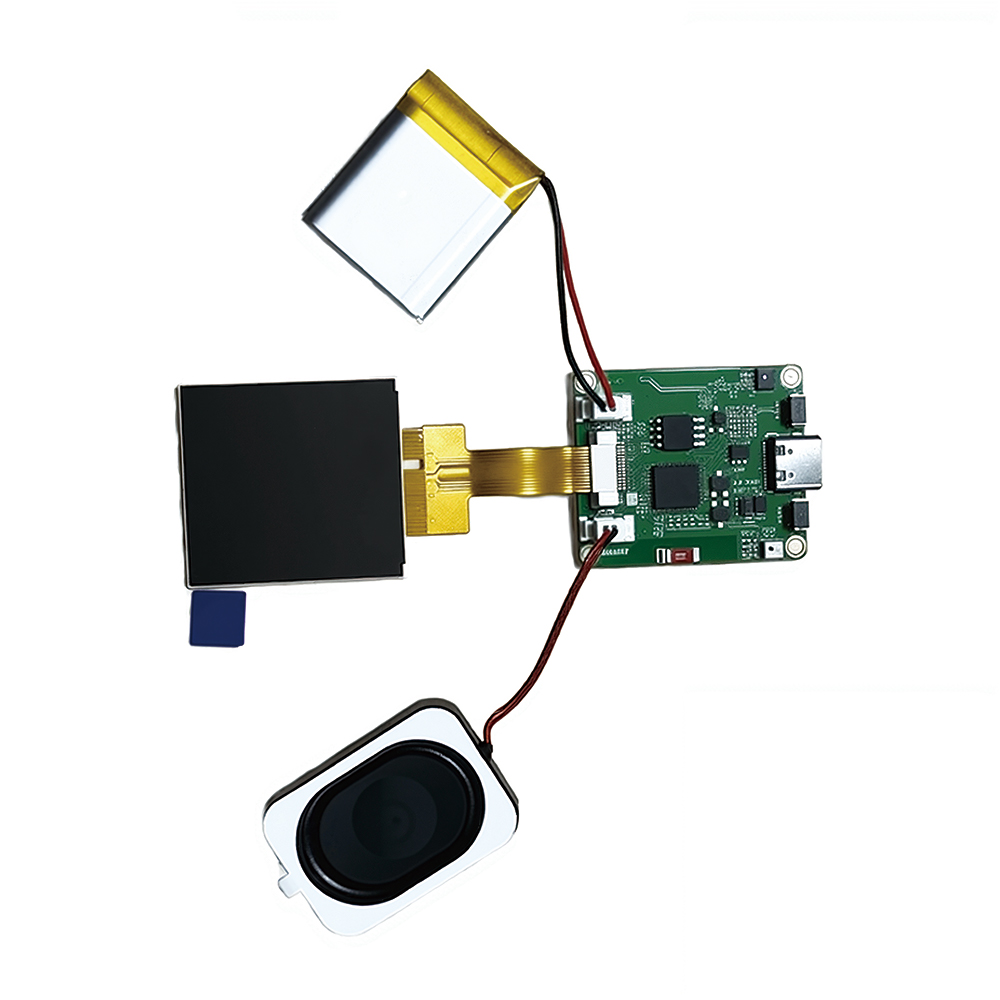

Portable medical devices (e.g., outdoor emergency ultrasound machines, POCT detectors) face unique challenges: frequent contact with alcohol/disinfectants causes metal corrosion, heavy weight increases carrying burden, and internal precision electronics demand high-quality enclosures with heat dissipation.

High-end aluminum alloys excel with tailored advantages:

- Disinfectant-resistant corrosion performance: Maintains equipment appearance and structural integrity despite chemical exposure;

- Lightweight design: Reduces hand-holding/carrying pressure for portable devices;

- Precision machinability: Creates special-shaped buckles and heat dissipation holes on enclosures;

- Excellent thermal conductivity: Assists heat dissipation of internal electronic components.

Its specific applications include medical parts needing “corrosion resistance + lightweight + precision heat dissipation,” such as portable ultrasound enclosures, outdoor emergency detection equipment frames, and internal precision brackets for POCT instruments.

Extreme environments (polar regions, rainforests) bring severe issues: low temperatures, high humidity, and large temperature differences cause ordinary metals to crack (due to icing and thermal stress), while heavy components limit drone-based transportation and deployment of monitoring devices.

High-end aluminum alloys tackle these challenges with key strengths:

- Extreme humidity/cold resistance: Resists erosion from high humidity and low-temperature condensed water, preventing rust and fracture of equipment brackets;

- Lightweight advantage: Facilitates drone transport, expanding deployment range of glacier monitoring sensors and rainforest ecological recorders;

- Combined high strength & machinability: Enables production of sensor fixing frames that withstand low-temperature stress, avoiding structural deformation.

Its specific applications include monitoring components requiring “extreme humidity/cold resistance + lightweight,” such as polar glacier displacement monitoring brackets, ecological sensor enclosures in rainforest high-humidity environments, and precision connectors for plateau outdoor weather stations.